Billennium Series – Tracked Spider Lift

Self-propelled, tracked spider lifts: the BT LINE range of aerial-work platforms changes the concept of working at height by combining the characteristics of self-propelled and wheeled-aerial platforms, with stabilised tracked-aerial platforms.

The goal was to create a single product that combined the key features of self-propelled, wheeled-aerial platforms, with stabilised tracked aerial platforms. Through extensive research and development, AlmaCrawler managed to develop the Billennium range which offers a morphologically unique product with a simpler user experience, and superior market adaptability. The end result caters to both the professional end-user, and the rental sector.

The B1570 and B1890 with a working height of 15m & 18m respectively, also have two different types of automatic stabilisation, Fixed (Visual) or Variable (Quick-PRO). There are also three power options available including, petrol engine (ETS version), diesel engine (EVO version) and full electric lithium (LTH version).

All versions showcase typical tracked platform size compactness (minimum width 0.78m) and a competitive maximum weight (2600kg, 2900 kg) to ensure transportability on traditional trailers.

With an operating outreach of 8.6m and 9.8m respectively, and a maximum load capacity in the basket of 230kg and 250kg, the Billennium Spiderbooms will also feature a series of new technological features:

- SPS (Self-Propelled Skilled System) – This new patent-pending system allows the use of the machine even without lowering the stabilisers, on slopes up to 10° longitudinally and up to 5° laterally. The platform can safely and directly be used up to 9m working heights, thanks to the advanced control and leveling systems of the machine.

- AWP (Adaptive Working Performance) – This new patent-pending system allows for the optimisation of the operational outreach. It calculates the stabilisation area in real time by measuring the angle of deployment of each individual stabiliser, the performance being determined by checking the actual stabilisation area in real time.

- Automatic Stabilisation – All Billennium models are equipped with the automatic stabilisation system as standard. Two choices include:

- A) Visual – Automatic stabilisation with a fixed area.

- B) Quick-PRO – Automatic Stabilisation with variable areas, it offers six different machine positioning configurations. Simple to choose through the onboard selector, it automatically interacts with the AWP system and gives the operator the best possible outreach performance.

- Undercarriage XXL – AlmaCrawler design which allows for an easier and safer daily loading / unloading as well as the selfpropelled capabilities of the Spiderbooms. This without sacrificing the typical size compactness (variable track 0.79 ÷ 1.39 m but with a longer track length – 2 m).

- ATS (Automatic Tensioner System) – Uniquely designed “ZERO MAINTENANCE” hydraulic system for the automatic tensioning of the track.

- Tasket Basket – The only resizable basket on the market, no disassembly needed, can go through narrow passages, and it extends from the minimum width of the aerial platform 0.79m to a comfortable-for-two 1.2m.

The Billennium Spiderboom was designed to complement AlmaCrawler’s already popular range of innovative tracked aerial platforms, including the Athena HE and Athena BL scissor lifts, the JIBBI telescopic boom lift, and the Multi Loader tracked carriers. Available with our intelligent, integrated anti-collision detection technology.

Through its all-terrain versatility for working safely at height, the Billennium Line is highly suited for construction and industrial applications, the arbor sector as well as building and park maintenance.

The Billennium range is available directly through Almac Pacific or our Australian exclusive national dealer, United Forklift and Access Solutions.

- Published in News

Collision Detection – Technology Capabilities for a Higher ROI

We won’t compromise on safety, reliability or performance which is why we offer intelligent, integrated anti-collision sensors on our Jibbi, Athena and Billennium ranges, safeguarding you, and your equipment.

During machine operation, our advanced anti-collision sensors create an obstacle-detection zone above the operator, monitoring for any overhead obstructions that may result in unneccessary injury, or equipment/structural damage. The main sensors are installed on the top rail of the platform and are always active during operation. If a proximity breach is detected, the sensor triggers an audio and visual alarm, while locking all functions of the machine. The operator must then release the control and assess the surroundings.

Lowering functions will remain active. Should the operator decide to continue with elevation, a 3-second delay before re-engagement will occur.

For optimum protection and unbeatable performance, contact Almac Pacific today.

- Published in News

Case Study – Uphire

The opinion of Nigel McKinley, the UpHire Managing Director

Whether the project is big or small, day or night, Uphire has the right equipment and hire solution for you. We of Uphire loves being first to market with new equipment, so back in 2016 when we first saw the unique capability of the Athena Bi-levelling scissor lift, Uphire had to have one, in fact we bought two, said Managing Director Nigel McKinley.

McKinley added “At the time the Athena 850 was a new machine in the Australian market and this unit offered something that other machines didn’t. The ability to level on slopes, uneven ground and inclines up to 20 degrees without outriggers was, and still is, something unique in our industry. This appealed to me and gave us a point of difference, which is important for any company. With a platform capacity of 250kg and a working height of 8 metres, the Athena 850 Bi-Levelling Scissor Lift is an exceptional machine for all your tasks. This machine can take on challenging landscapes and is designed to provide stability on uneven terrain, ensuring workers are protected and are able to work on the platform safely.”

What problem did the machine solve for the UpHire customer

Uphire, located in Sydney, added two more Athena 850 BL‘s in 2017 and a Jibbi 1250 EVO and the Athena 1090 EVO to its fleet in 2020. The features on these machines make it an easy choice for the “hard to get to” jobs where bigger conventional booms and scissors can’t because of size, weight and length restrictions for certain jobs. Recently Uphire had a customer that needed the Jibbi 1250 EVO to do high pressure water cleaning on a building in the City of Sydney. The light weight and rubber tracks of the Jibbi 1250 EVO was ideal as it was working on a foot path where there were underground services below. Overnight when the machine is packed up it’s nice and compact and doesn’t take up too much space and an added bonus is that it is much easier for a smaller truck to transport it through the busy CBD. The Athena 1090 EVO was perfect for another job, where a conventional scissor couldn’t fit because of the tight narrow access and there was weight restrictions as well. Steel plates were needed to be placed over a pit and then drive the Athena 1090 onto the plates to get close up to the building. The site engineers were amazed of the Bi Levelling capabilities along with the compact size of the machine. I can’t think of many other machines that would of been able to this job.

Contact Uphire today to secure one for your next project:

Ph: 1300 874 473

- Published in Case studies, News

JIBBI 1670 EVO: the evolution of JT-LINE

AlmaCrawler presents the new JIBBI 1670 EVO Self-propelled Telescopic Crawler Boom

JIBBI 1670 EVO represents the evolution of the JT series, not only in terms of working height but also in terms of technology, versatility and innovation. This new addition stands out not only due to its maximum working height of 16 m, but also for the operating reach that ranges from 6.7 to 8.5 m and the possibility for the operator to travel up to a moving height of 9 m.

Introducing a new feature, a variable undercarriage track width with different track-opening configurations that allow the operator to work in narrow spaces but then stabilize to achieve full working height – operating track widths: 1.35 m, 1.90 m, 2.20 m and 2.45 m.

A newly introduced feature, born as a result of our research & development department’s work, is the new remote connected control panel that through the dedicated APP “MyAlmac Control Panel” allows the continuous monitoring of the machine’s service status, while offering the possibility to interact/modify the operating parameters adapting them to the requirements of your fleets.

Like our previous models, the JIBBI 1670 EVO uses the automatic levelling system “Dynamic Levelling”, our globally recognized technology, able to compensate gradients of up to 22° (40%) during transport conditions travelling and the Pro-Active Levelling technology, which works to cover the “driving at height” operations.

Equipped with a 3-cylinder Yanmar diesel engine (14.1kW – 19.2 HP), this self-propelled unit has a total weight of only 3850 kg with a ground load of 3.1 KN/m2. Its compact size allows the machine to be used in restricted spaces, thus ensuring ease of use and movement. In transport conditions JIBBI 1670 EVO showcases a minimum width of 1.35 m, a stowed height of 1.99 m and a full length of 5.17 m which can be further reduced to only 4.40 m by quickly and easily dismounting the basket. The standard basket is 1.4 m wide basket (designed to allow the operator to position it in the same width of the machine), but we also offer the option of a slightly wider 1.8 m basket, designed to favour the comfort of the operators. Both versions have the possibility to rotate +/- 70° while guaranteeing a maximum capacity of 230 kg. The optional configuration is completed by the 200 Series Winch Kit already presented and promoted on the JIBBI 1250 and 1270 range.

What technologies are used?

Like all the AlmaCrawler products, the JIBBI 1670 EVO is standardly equipped with cutting edge technology that enhances its performance mix, combining weight, dimensions, working height and operating reach and establishing it as a revolutionary product for the world of lifting, designed to simplify, speed up and increase productivity while catering and satisfying safety standards for operators:

- DWP – Dynamic Working Performance, dynamic, real-time management of the performance of the machine based on the real working conditions. The system, subject to patent application, operates by simultaneously analyzing the slope parameters of the ground, the configuration of the roadway used and the instantaneous load in the basket, dynamically determining the best available working performance so that the operator can remain focused on his work at height.

- Safe-Lock System, a system to prevent track spillage from the tensioning wheels, both toothed.

- Ultrasonic anti-collision system, to protect operators in the basket with anti-crush barrier function in the two directions of movement of the basket (in the upper and lower part). This system protects operators from unforeseen and accidental impacts.

Would you like more information?

Contact us to receive more information on the JIBBI 1670 EVO

- Published in News

Temporary Full Expensing: an expansion of the instant asset write-off scheme

Don’t delay your next equipment purchase. Your business could now write-off any eligible expense immediately, at any cost, until June 2022 in an expansion of the Government’s Instant Asset Write-off scheme.

The measure will apply to eligible assets purchased from 7:30pm (AEDT) on 6 October 2020 and first used or installed by 30 June 2022. It applies to businesses with an aggregated annual turnover of up to $5b.

This scheme is referred to as ‘temporary full expensing’. Full expensing in the first year of use will apply to new, depreciable assets and the cost of improvements to existing eligible assets.

For businesses with an aggregated annual turnover of <$50m, full expensing also applies to second-hand assets. Businesses with an aggregated annual turnover between $50m & $500m can still deduct the full cost of eligible second-hand assets costing less than $150,000, that are purchased by 31 December 2020. Businesses holding assets that are eligible for the enhanced $150,000 Instant Asset Write-off will have an extra six months, until 30 June 2021, to first use or install those assets.

Contact us today on 0402 982 999 for a no-obligation discussion.

The information provided here is general advice only and has been prepared without taking into account your objectives, financial situation or needs. Please speak to your accountant or tax agent for specific tax advice.

- Published in News

Electric self-propelled crawler lifts: the Green soul of Almac

Almac has launched its new 16 m, 100% electric, zero emission, self-propelled telescopic boom: the JIBBI 1670 LTH.

Suitable for operating in environments where low noise and exhaust gas emissions are required, the 16-metre JIBBI 1670 LTH electric platform is equipped with a high-performance 300Ah-48V lithium battery and two 20Ah-48V chargers, which allow rapid recharging in just 6 hours, thus reducing downtime.

While maintaining the same operating performance as the EVO version (including: maximum working height of 16 m and 9.8 m moving height, an operating reach of 8.5 m, as well as an undercarriage with four different configurations), the LTH model has the advantage of operating without emissions by exploiting hydraulic power for all aerial movements.

In which places is it suggested to use the self-propelled JIBBI 1670 LTH?

The JIBBI 1670 LTH is particularly suitable for indoor, outdoor and sensitive areas, such as for example:

- Hospital

- Shopping centres

- Industries

- Residential areas

- Urban construction sites

- Historical centres

- Churches

The self-propelled JIBBI 1670 LTH is a machine that thanks to its qualities allows to have a lower environmental impact and at the same time to safeguard the health of the operators in case of long-term use.

Almac’s innovative electric machines

To satisfy the needs of customers operating in sectors that require the utmost attention to the environment, the Almac team has designed and developed, in addition to the JIBBI 1670 LTH, another machinery equipped with electric motors.

The development of electrical machinery by Almac’s team aims to offer its customers the possibility to choose zero emission self-propelled crawler lifts, suitable for working both indoors and outdoors.

Among Almac machines with a green soul, it is possible to find:

- The self-propelled telescopic boom JIBBI 1250 ELC with electric engine;

Thanks to these versions of electric self-propelled platforms, Almac is able to satisfy the needs of its customers who are looking for high performance machinery to carry out work at height in complete safety, without neglecting respect for the surrounding environment.

- Published in News

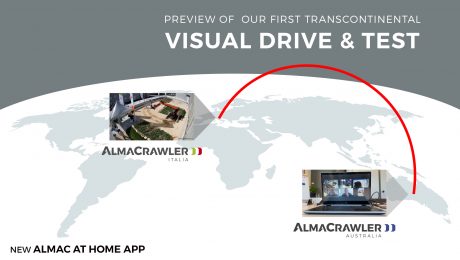

Almac At Home: Drive and Test our Aerial Platform directly from home

The new service to test Aerial Platform with an simple App

Almac launches a new service to all its customers: ALMAC AT HOME, an application specifically designed to carry out a driving test of aerial platforms directly from home, anywhere in the world the customer is located.

How is the driving test performed with ALMAC AT HOME?

The online operator can enjoy a real driving experience, in a dedicated area created at the company Viadana Headquarters, in the province of Mantua, where the Almac platforms can be tested, controlling the machine directly from the App that faithfully reflects the graphical interface of the real control instruments.

ALMAC AT HOME consist in a complex network of cameras positioned in the new “Crawler Park” demo area, centralized production control and internally developed bespoke software. These elements allows a unique and realistic experience driving test experience of Almac platforms.

The advantages of the new service launched by Almac

The technology implemented with ALMAC AT HOME shows how Almac is an innovative brand not only in terms of products but also in terms of services tailored to customer needs.

Industry professionals, using the new ALMAC AT HOME App, from anywhere in the world, will be able:

- View the machine as a whole and in detail

- Check work performance in real time

- Carry out a demo – a real driving experience of a real physical machine, in real time

It will be possible booking their place for an “Almac at Home” demo date – demos that can accommodate up to 100 users at the same time, thus breaking down any geographical distance.

Almac has decided to propose this new technology by implementing the ALMAC AT HOME App to meet its customers, increasing the services offered related to sales and technical support.

By developing this unique and innovative service, Almac once again proves to be attentive to the needs of its customers, both nationally and internationally.

ALMAC AT HOME is directed to all reference markets and brings innovation and services of the company ensuring operational, commercial and technical proximity to all customers.

If you would like to take advantage of ALMAC AT HOME and test the working of Almac aerial platforms, send us your request by filling in the form in the Visual Demo page.

Download the press release of the ALMAC AT HOME App presentation

- Published in News

Government Tax Incentive

DON’T DELAY YOUR NEXT EQUIPMENT PURCHASE

Government $150,000 Instant Asset Write-Off

$150,000 Instant Asset Write-Off

Eligible assets will be able to be written off for this financial year meaning that you will pay less in tax. Any new or used equipment with a purchase price of up to $150,000 (exc GST) purchased and installed* between 12 March and 30 June 2020 will be eligible. There is no limit to the number of assets purchased that can be written off under this program. You can purchase multiple assets which total more than $150,000 so long as each individual asset is less than $150,000. Businesses with an aggregated annual turnover of less than $500 million will be eligible until 30 June 2020.

Short term opportunity offered by the Government

From 1 July 2020, this offer will no longer be available and the instant asset write off will return to the normal amount of only $1,000 for businesses with a turnover of less than $10 million.

50% Instant Depreciation

Eligible assets purchased and installed from 12 March 2020 and 30 June 2021 will be eligible for a 50% instant depreciation. Businesses with an aggregated annual turnover of less than $500 million will be eligible until 30 June 2021. New assets only. This incentive is available for 15 months.

Contact us today for a no-obligation discussion.

- Published in News

Appointment new General Manager for Almac Pacific

AlmaCrawler announces New General Manager for its subsidiary Almac Pacific

Almac Italia, the Italian manufacturer of the innovative bi-levelling Scissor lift and telescopic Boom lifts is pleased to announce Bob Mules as the new General Manager for its Pacific operative branch, Almac Pacific.

Mules, a long-time experienced presence in the industry, spent his first 17 years in the Rental Industry, 13 of those years were with Wreckair Hire, acquired by Coates Hire in 2002, before he decided to “cross the line” and spend the past 19 years with Access manufacturers (OEM’s), with the last 10 years as the General Manager of Australia and New Zealand for JLG.

Bob Mules commented: “I’m excited to join such a dynamic company that is driven by innovation and providing the highest standard in safety in daily use. The AlmaCrawler products, with their self-leveling capability are definitely industry leading. Being able to combine my years at the helm of a leading company in the sector with Almac’s technological initiative, is an exciting challenge and opportunity.

Considering the strong appreciation of the customers towards the quality and after sales support of the Almac products, I look forward to working closely with our National Retailers – United Fork Lift Equipment, Youngman & Richardson and Alfasi Hire, the rental companies and service providers. I aim to strengthen our current partnerships and to ensure that we provide them an exceptional customer experience on a daily basis.”

Andrea Artoni, General Manager and Owner of Almac Sri. commented: “Nowadays after 7 years of our history, Almac is being recognized as one of the most innovative and dynamic companies within the AWP industry, as shown by its numbers, growth rate, and the expansion of its product range and increasing sales network worldwide.

The Pacific region is an extremely strategic area for Almac. In fact, our products have already been implemented in the rental fleets of the biggest players. For this reason, today our Company wants to organize, consolidate and reinforce its presence, especially looking at the upcoming development of our range in the next three years.

So, I’m very happy that Bob Mules is joining our Almac Pacific’s team. He will definitely bring his experience and market knowledge to support us in making this next step. The appointment of Bob compliments the new recent strategy that saw us establish our new operational headquarters near Melbourne. This dedicated warehouse, for spare parts and products’ stock, has been set up to support our direct customers and our national retailers, United Equipment for Australia, Youngman & Richardson in New Zealand and Alfasi Hire in Malaysia.”

Mules will assume responsibility for the Almac-Pacific business, starting on May 4th.

All of the Almac team are really excited about the future and looking forward to the challenges ahead as we build our business throughout the market of Australia and New Zealand.

- Published in News

JIBBI 1250 EVO in AUSTRALIA

The first JIBBI 1250 EVO is coming in Australia!

Almac introduce in our range the revolutionary JIBBI 1250 EVO, the self-propelled telescopic boom with unique performances and winner of Product of the Year at the IAPA AWARDS in the category “Self Propelled Booms & Atrium Lifts”. This machine have a working height of 12.2m and equipped with a dynamic and automatic levelling system, that ensure to operate on rough terrain and / or on steep slopes. The fist JIBBI will coming in Australia at Duralift in October 2019!

- Published in News