Secondary Guarding EWP

Elevated Work Platforms (EWPs) are an integral part of the hire and rental industry, with equipment manufacturers now advancing machine capabilities as quickly as new technologies emerge and evolve across the world.

Equipment owners balance a wide range of considerations when it comes to choosing their next asset purchase, including efficiency and productivity, the total cost of ownership (TCO), utilisation, hire rates, and of course resale value. However, arguably the most critical component is that of operator safety.

“Incidents relating to EWPs have resulted in death and serious injury, with at least 9 fatalities and 355 workers’ compensation claims during the period 2015-2019”.

https://www.safeworkaustralia.gov.au/media-centre/news/new-guide-managing-risks-elevating-work-platforms

There are a number of common hazards related to the use of EWPs, including uneven/unstable ground (refer to Almac bi-levelling technology capabilities for solutions), machine failure, falling objects, weather-related hazards, and traffic/pedestrians. Further to this, the range of motion available on some modern EWPs, introduces an increased likelihood of a crushing incident for operators and/or passengers when the equipment:

- is used near overhead structures such as roofs, structural beams, trees, pipework.

- platform moves unexpectedly while near an overhead structure due to uneven/unstable ground, ineffective use of the EWP controls, or malfunction of the EWP/controls.

- operator becomes distracted while manoeuvring the EWP.

Before operating EWP in, around, or near fixed structures, SafeWork Australia has identified that a person conducting a business or undertaking (PCBU) must eliminate crush risks by identifying hazards and assessing and controlling risks where practicable to do so. https://www.safeworkaustralia.gov.au/safety-topic/hazards/elevating-work-platforms/managing-risks

SafeWork Australia has developed guidance for managing the risks of EWPs which includes avoiding the use of EWP that is not fitted with secondary guarding when there is a risk of crushing. Various secondary guarding devices may help prevent crush or trap injuries, depending on the type of EWP and work being done.

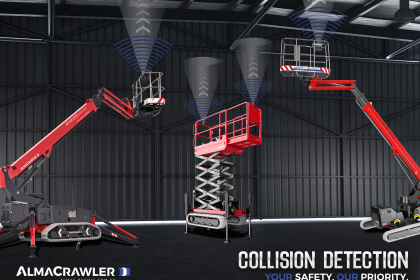

AlmaCrawler will not compromise on safety, reliability, or performance, which is why intelligent integrated anti-collision sensors have been engineered (compliant to Australian and New Zealand standards) to prevent the movement of their EWPs into unsafe areas. This feature is available on the JIBBI, Athena, and Billennium range of EWPs – safeguarding you, and your equipment.

During machine operation, Almac’s advanced anti-collision sensors create a large proximity-detection zone above the operator. This sensor zone monitors for any overhead obstructions that may result in unnecessary injury (or death), damage to the equipment and/or surrounding structures from impact.

The main sensors are securely fitted to the top rail of the EWPs platform and are always active during operation. If a proximity breach is detected, the sensors trigger both an audio and visual alarm, while simultaneously locking any further functions of the machine. Lowering functions will remain active at this point. The operator must initially release the control and assess the surroundings to determine the proximity risk that has been detected.

Should the operator decide to continue with elevation, a 3-second delay is experienced before re-engagement can continue.

While this significant secondary guarding technology will undoubtedly minimise the risks involved in working at heights, accidents can, unfortunately, occur at any time.

Employers must ensure that operators are fully trained on how to use the EWP safely. Operation manuals and manufacturer specifications should always be followed, ensuring that safety features are not ignored, modified, or removed at any time. Safety standards, signage, PPE, training and checklists all form part of controlling risks in relation to the use of EWPs.

Emerging technologies such as AlmaCrawler’s collision detection capabilities, coupled with regular machine maintenance and other preventative measures against EWP hazards, will ensure more workers return home safely to their families, at the end of the day.

For optimum protection and unbeatable performance, contact Bob Mules on 0402 982 999 or online here.